The Ultimate Guide to Searching For Reliable Welding Inspection Milwaukee Professionals

The Ultimate Guide to Searching For Reliable Welding Inspection Milwaukee Professionals

Blog Article

The Duty of Welding Assessment in Stopping Failings and Enhancing the Longevity of Welded Structures and Parts

Welding evaluation is an essential component in the lifecycle of welded frameworks, serving as a proactive procedure against potential failures that can endanger safety and capability. By methodically recognizing issues such as porosity or incomplete combination, inspectors can considerably improve the durability of vital parts. The application of varied inspection strategies not only ensures conformity with industry requirements however also cultivates a durable culture of high quality assurance. The implications of ignoring this essential practice can be profound, raising questions about the true impact on architectural honesty and long-term performance. What are the very best techniques that can additionally boost evaluation efficiency?

Relevance of Welding Assessment

Welding evaluation works as a crucial secure in the integrity of welded structures, guaranteeing that they meet rigid security and top quality requirements. The significance of this procedure can not be overemphasized, as it plays an important function in determining potential issues before they escalate into disastrous failings. By rigorously reviewing welds, assessors can validate adherence to develop requirements and governing needs, thereby reducing dangers associated with structural compromise.

Furthermore, reliable welding assessment improves the longevity of parts, as it permits the very early discovery of problems that might result in damage in time. This positive strategy not only expands the service life of bonded frameworks yet also promotes reliability and functional effectiveness. In markets such as building and construction, aerospace, and automobile, where security is critical, the evaluation process is indispensable.

In addition, welding assessment cultivates a society of quality control within organizations, motivating adherence to finest practices and continuous enhancement. By purchasing extensive assessment procedures, business can enhance their credibilities and maintain consumer depend on. Eventually, the significance of welding examination exists in its capability to support security, quality, and durability in bonded frameworks, making it an essential part of engineering stability.

Common Welding Defects

Numerous usual welding issues can compromise the stability of bonded frameworks, causing potential failings otherwise resolved. Among these issues, porosity is just one of one of the most prevalent, identified by the visibility of tiny gas pockets caught within the weld metal. This can substantially weaken the joint, resulting in decreased architectural honesty.

An additional problem is incomplete combination, which takes place when the weld metal falls short to adequately fuse with the base material or previous weld layers. This absence of bonding can create weak points that may fail under stress and anxiety. In a similar way, absence of infiltration describes inadequate depth of weld steel, stopping the joint from achieving its desired stamina.

Splits can likewise establish throughout the welding process, frequently as a result of quick air conditioning or unsuitable welding criteria. These cracks might propagate under load, resulting in disastrous failures. Additionally, excessive spatter can prevent the weld's top quality by presenting contaminants.

Assessment Strategies and Approaches

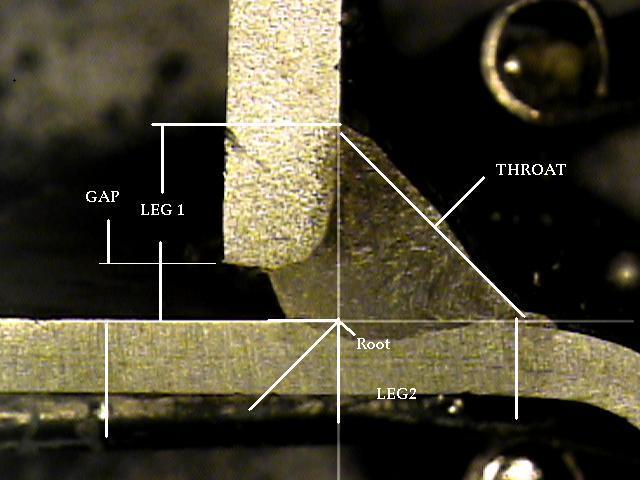

Reliable assessment techniques and techniques are vital for making sure the integrity and longevity of welded structures. A thorough examination regime employs a range of non-destructive screening (NDT) techniques to detect potential flaws without jeopardizing the bonded components. Amongst the most generally used methods are aesthetic inspection, ultrasonic testing, radiographic testing, magnetic bit screening, and color penetrant screening.

Visual assessment acts as the first line of defense, permitting inspectors to recognize surface area issues such as cracks, misalignments, or insufficient combination. Ultrasonic testing uses high-frequency acoustic waves to spot internal problems, giving in-depth info regarding the product's honesty. Radiographic screening uses X-rays or gamma rays to picture the inner structure of welds, enabling the recognition of spaces and inclusions.

Magnetic particle screening is efficient for identifying surface and near-surface suspensions in ferromagnetic products, while dye penetrant testing highlights surface-breaking problems using tinted dyes. Each technique has its special advantages and constraints, requiring a critical mix to achieve comprehensive inspection coverage. Applying these methods systematically ensures that any type of prospective concerns are determined early, cultivating the integrity and sturdiness of welded frameworks.

Effect On Structural Integrity

The integrity of a framework is considerably influenced by the quality of its welded joints, as they act as crucial points of strength and stability. Badly executed welds can bring about stress focus, exhaustion failings, and inevitably, catastrophic view it now architectural collapse. The reliance on welding as a key methods of signing up with products necessitates extensive evaluation procedures to make certain that welds satisfy well-known criteria and specifications.

Deficiencies in weld high quality, such as incomplete fusion, splits, or porosity, can endanger the mechanical properties of the joint, influencing load-bearing capacity and overall efficiency. When these problems go unnoticed, they can propagate under operational anxieties, causing a decline in structural stability over time. Thorough and regular assessments are important in identifying these weak points prior to they rise right into substantial failures.

In addition, the influence of environmental factors, such as deterioration, can be exacerbated by inadequate welding practices. Hence, ensuring top notch welding via vigilant assessment not only advertises prompt structural dependability yet also expands the life span of elements. Welding Inspection Milwaukee. Eventually, the investment in appropriate welding examination is a crucial method for safeguarding versus structural failures, thus enhancing the longevity and safety and security of bonded frameworks

Best Practices for Effective Evaluation

Applying systematic inspection protocols is necessary for making certain the integrity of welded joints. Efficient evaluation starts with the development of thorough checklists tailored to the certain welding procedures and products included. These lists must incorporate visual assessments, non-destructive testing (NDT) approaches, and paperwork evaluation to guarantee that all elements of the welding process are scrutinized.

Training and qualification of examination employees are vital components of find here an effective assessment program. Examiners should be well-versed in different NDT methods, including ultrasonic, radiographic, and magnetic bit screening, to properly identify flaws such as splits, porosity, and incomplete combination.

Timely assessments need to be scheduled at numerous stages of the welding process-- pre-weld, during welding, and post-weld-- to capture any type of prospective problems early. Furthermore, maintaining comprehensive documents of examinations fosters responsibility and facilitates future examinations.

Final Thought

Welding assessment is important for recognizing problems and making certain the stability of welded frameworks. Eventually, efficient welding evaluation not just safeguards architectural stability but additionally adds substantially to the total integrity and toughness of bonded joints.

Welding examination is an essential part in the lifecycle of welded frameworks, serving as a positive step against possible failings that can endanger safety and capability.Welding assessment serves as an important secure in the integrity of bonded structures, guaranteeing that they fulfill rigid safety and security and high quality requirements. Welding Inspection Milwaukee. Ultimately, the relevance of welding examination exists in its capacity to copyright safety, quality, and durability in bonded frameworks, making it a basic element of engineering stability

Inevitably, the investment in appropriate welding assessment is an important method for safeguarding you could check here versus architectural failures, thereby enhancing the durability and security of welded frameworks.

Welding examination is necessary for determining flaws and making certain the integrity of welded frameworks. Welding Inspection Milwaukee.

Report this page